Will you drive your vehicle 50,000 miles without changing the oil? If “No” then the same logic holds true for your home comfort system. Regular HVAC preventative maintenance from BHMS is the best way to ensure trouble-free operation and peak performance. Our pre-season maintenance is designed to avoid a system failure in severe hot or cold weather when you need it most, and it can also keep your energy bill from getting out of control.

If the old adage holds true “an ounce of prevention is worth a pound of cure”, then an HVAC preventive maintenance should be performed:

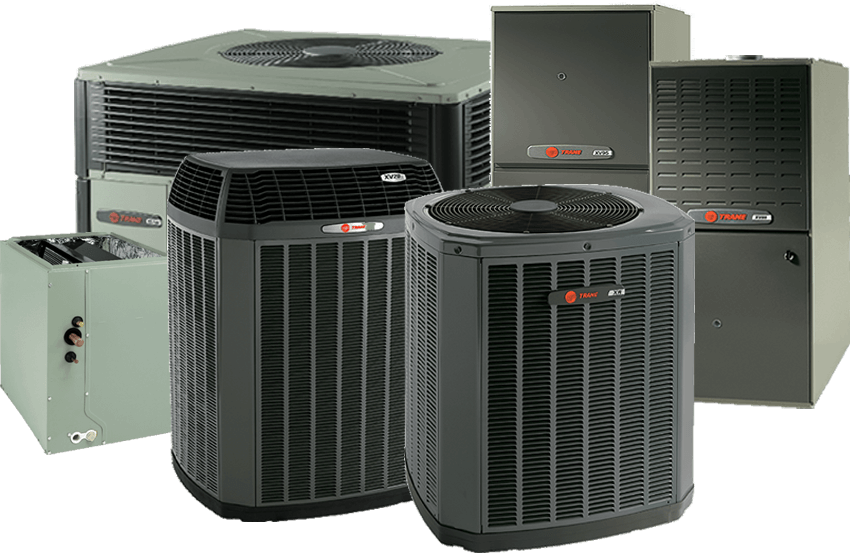

BHMS through our BHMS Service Club provide priority service for our customers who have an annual service/maintenance agreement with us. Bi-annual preventative maintenance will ensure that your system runs as efficiently as possible. Having been HVAC Contractors for many years, we offer you an Outdoor Unit Checklist you can use: